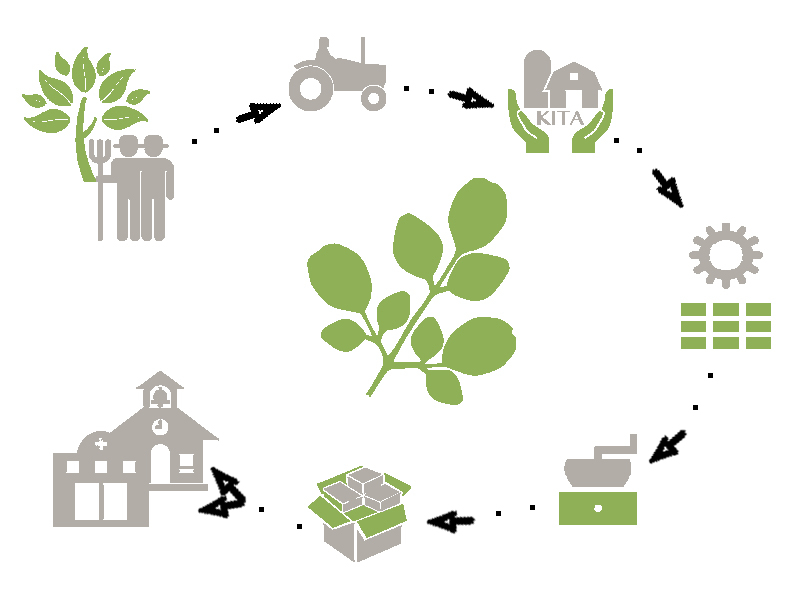

For the efficiency and costs it is essential to save time in the whole production process. When the Moringa leaves are ready for harvesting; they will be picked in large numbers. First the leaf petiole will be cut off from the tree, followed by washing. Washing of the leaves is to be done in a solution of clean water and saline to rid the leaves of microbes after wish they will get drained of excess water. This is followed by stripping the leaves. During and after stripping damaged leaves are eliminated from the batch. After this the leaves should be dried in a solar dryer, leaves cannot be dried in open air as contact with dust, insects and rodents will have a significant negative impact on the quality of the powder. It is important to let the leaves dry in a well-ventilated room to prevent any mould from growing.

When you are left with, dry and clean leaves the next step is to grind and mill the leaves. As of now KITA uses a mortar and pestle to create the powder which is a labor-intensive time-consuming process.

Before the powder is packed, it should be sieved to remove the remaining stems. When packaging sealing the product from water damage should be taken in consideration. For conservation of the nutrients over a longer period of time, the product should be kept in a cool and dark environment. (Teeffelen,T.2014)