One possible technological solution that can, to a large extent, solve Texel’s inorganic waste problem is biodegradable packaging. Solid waste predominantly consists of packaging waste (In developed countries, food packaging represents 60% (Northwood and Oakley-Hill, 1999) of all packaging.). Consumer goods without any kind of packaging is unfathomable nowadays. Even though theoretically, 93 percent of packaging waste from the fast food industry, for instance, is recoverable, only 29 percent ends up being recovered because of non-working waste management practices, obscure status of commercial waste and municipal autonomy (Aarnio, Hamalainen 2007) .From an economic perspective, poorly managed waste presents adverse effects on the health of the available working populace and on the economic efficiency of waste management process. Downstream waste management costs are higher than the ones that would have been incurred if waste was properly managed in the first instance. Piled up municipal solid waste also contributes to greenhouse gas emissions like methane, affecting both local and global environment (Hoornweg, Tata, 2012). The only logical solution to reduce the economic and environmental impact of inorganic waste is to adopt a technological option that has minimum environmental burden per product. Innovation in the field of packaging materials is the only feasible solution to de link greater consumption and the increasing (tourist) population in Texel from a corresponding upsurge in waste generation. Packaging materials are already lighter, more durable, more ecofriendly than fifty years ago. Incremental technological advances has enabled us to reduce the spurious effects of waste, but for a more comprehensive solution, we need a sustainability transition i.e., a major, long term technological change in the way packaging is fulfilled.

The development of biodegradable and edible packaging reduces the environmental burden, through:

- Employing more sustainable raw material sources (feedstock, marine food processing industry waste) for packaging material instead of crude.

- Reducing spoilage of food products.

- Mitigating detrimental effects of packaging waste on health, environment and the local economy

- Promoting integrated waste management practices, thus reducing landfill.

This approach leads to natural resources conservation, recyclability, better product shelf lives, as well as generation of new, innovative design and use. Total biodegradation of biopackaging produces environmentally friendly benign products such as CO2, water and quality compost (Tharanathan, 2003 & Davis,Song,2006).

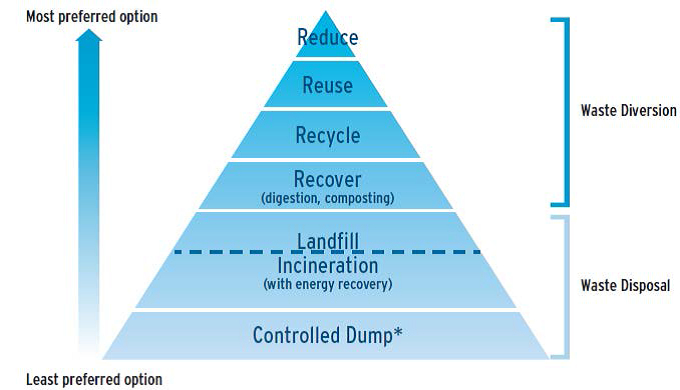

In their paper, WHAT A WASTE: A Global Review of Solid Waste Management (2012), Hoornweg & Tata suggest a waste management hierarchy that is based on financial, environmental, social and managerial considerations (see figure 4.1).The most preferred waste management solution is reduction of waste at the source. The paper describes that this can be achieved by redesigning the product and changing patterns of production and user practices. Adoption of biopackaging is a quintessential waste reduction at source technique and it should be preferred over other options like recycling, landfilling, incineration etc.

Fig. 4.1: Waste management hierarchy (Hoornweg & Tata, 2012)

4.2.1 Current state of the biodegradable packaging system.

Biopackaging materials can be split into biodegradable polymers and biopolymers. Biodegradable polymers are synthetic polymers possessing a certain degree of inherent biodegradability, for instance: polycaprolactone, polyhydroxybutyrate or they are plastics chemically designed to assist biodegradation (Bastioli et al., 1994) whereas biopolymers are naturally occurring long chain molecules like proteins, polysaccharides or they are materials derived from these natural polymers. Polysaccharide (starch) based packaging material is currently the most popular among all the commercially available options because starch is annually renewable, its abundant (15 million tonnes are produces in Europe and half of it is used for non-food applications (Lockes,1998) and its inexpensive(Petersen et al.,1999). In Europe, starch based polymers has cornered 62 percent of the market due to the continent’s large starch based capacity and their use in many applications (Coon, 2013).

Significant technological development has enabled biopackaging to achieve characteristics of traditional petrochemical based plastic packaging. Among these are commercially available materials based on or derived from starch such as Mater-BiTM (www.materbi.com),NatureWorksTMPolylactide(www.cargilldow.com),BioskaTM(www.plastiroll.fi),BioplastTM(www.biotec.de),SolanylTM(www.biopolymer.net),PotatopacTM(www.potatoplates.com),GreenfilTM(www.greenlightint.co.uk) and Eco-FoamTM(www.eco-foam.com).

Even though the costs involved are higher than their plastic equals, and a complete replacement of synthetic packaging is impossible, biopackaging possesses numerous avenues to substitute conventional packaging such as: (Tharanathan, 2003)

• Use and throw, disposable packaging materials.

• Routine consumer goods for day-to-day use, such as plates, cups, containers, egg boxes, etc.

• Disposable personal care napkins/ sanitary pads, diapers etc.

• Lamination coating.

The four major markets for biodegradable materials are: (Nayak, 1999)

- Food packaging.

- Non-food packaging.

- Personal and health-care disposal.

- Consumer goods.

Advancement in Biopackaging technology has led to development of products like MONODOSETM(www.monosol.com)- water soluble pouches for detergents, agrochemicals, insecticides, AQUAFILM®(www.monosol.com) -dissolvable laundry bags and flushable liners and bags and medical delivery systems and devices(David & Song,2006).

4.2.1 The Socio-Technical system for biodegradable packaging:

In this section, I elaborate on the different elements that will undergo transformations in the sustainable transition towards biodegradable packaging. To do so, we will use the concept of socio-technical systems (STS), regimes and niches from Geels (2002) and Pesch (2015).As defined in section 1.1, the STS is an interconnected, interdependent set of elements such as the technology itself, the symbolic meaning of the technology in popular culture, the customer preferences and user practices, the industry structure, regulatory bodies, related infrastructure, maintenance, distribution networks etc. Regimes are the existing way of doing things: the existing way of searching for solutions, designing products, manufacturing them; the existing way of framing expectations and assigning value. Regimes are what stabilize incumbent socio-technical systems. Niches, unlike regimes, are protective application spaces for new technology. Niches are spaces for pilots and action-learning experiments with the new technology. Niches enable learning regarding application of technology, expectations and visions, networks and the technical features. The STS/Regimes works in a coordinated manner to fulfil a societal functions, in this case, the ability to store products for lengthy periods, to provide ease of transport, create sales appeal, disposal of packaging waste etc. Figure 4.2 depicts the socio-technical system for biodegradable packaging.

Actors in the Socio-Technical Configuration:

I now analyse the stakes of each stakeholder involved in the ST regime in biopackaging.

1. Industry Structure:

I have split up the packaging industry into manufacturers of packaging films and coats and packaging solution providers, brands that use packaging materials for their products, supermarkets and point of sale.

.

Fig. 4.2: Socio-technical system for biodegradable packaging.

Incumbent manufacturers of packaging material and packaging solution providers may resist a transition to biopackaging as it could render their existing design base, engineering & managerial skill, and production processes obsolete. They would rather continue with the incremental innovations in plastic packaging through application of regime inertia, unless there exists a regulatory environment and incentive structure that fosters an entrepreneurial mind-set. These actors operate beyond the context of Texel. Necessary regulatory and incentive mechanisms are thus the territory of the Dutch government or even the European Union.

Consumer goods firms use packaging for the following functions: (Davis, Song, 2006)

- To provide protection from physical damage, contamination and deterioration.

- To give sales appeal.

- To ensure the product identity is easily recognizable.

- To give information about the product.

- To optimize distribution and storage costs.

- To provide consumer convenience and safety.

The stand firms take will depend on whether biopackaging fulfils these criteria. Firms like the manufacturers of packaging, may resist the transition unless they are incentivised or mandated to do so by the Dutch government for instance. The use of biopackaging may project the brand in a favourable light to local consumers or tourists in Texel who are conscious of their ecological footprint. This product differentiation can boost sales. Supermarkets and points of product sale aim to minimize storage and distribution cost while optimizing consumer convenience and safety through packaging. Supermarkets may resist storing goods using biopackaging if the shelf life is low or if costs involved are high

2. Regulatory bodies.

The potential of biopackaging cannot be fulfilled unless regulatory bodies such as the Municipality of Texel, the Dutch government or the European Union (EU) come up with frameworks that incite investment in biopackaging technology and incentives for its adoption. For the biopackaging market to develop, regulatory bodies have to set up regulatory systems, introduce industry standards, necessary certifications and certification systems. Thus, regulatory bodies have a prominent role in creating the sociotechnical regime. As the central control entity, regulatory bodies have the power to significantly change the status quo as a change in regulations in favour of biopackaging will cause a change in other elements of the regime like infrastructure, industry structure, and user expectations.

3. Customers and the symbolic meaning

The frequent usage of packaged products gives rise to customer preferences, expectations and user practices. Interaction of the customer with media and social groups gives rise to symbolic meaning. The customer expects the packaging to provide him with the convenience of elongated storage (in case the product is perishable), he expects the packaging to carry information on the product, the consumer will expect the packaging to enable him to easily transport the product, provide accessibility to the volumes he requires and for the packaging to withstand some duress. Biopackaging must serve these functions. Biopackaging costs may be passed on to the consumer and this may lead to resistance. Consumer education (especially for the tourists) scale economies are vital to customer acceptance of biopackaging.

The consumer can have subjective preferences, user practices of handling and disposing the packaging. The symbolic meanings that packaging holds are that of freedom and loyalty. Freedom of choice of brand, of volume; freedom of mobility. The packaging helps the user identify his favourite brand of product, thus contributing to strengthening of brand loyalty. Biopackaging should thus live up to preferences, expectations and symbolic meanings to win customer support for transition. For instance, the potential penetration of edible films and coatings will be shaped by consumer acceptance that is determined by organoleptic characteristics (flavour, appearance, sensory compatibility with coated/packaged foods), safety issues relating to potential toxicity and allerginity and cultural hesitance to the utilization of new artefacts (Han and Gennadios, 2005).

The municipality of Texel, consumer brands, supermarkets and lead customers have a critical role to play in the propagation of biopackaging. Lead consumers (sustainability conscious locals or community groups) in Texel who are the first to perceive the value of biopackaging like lower energy,non-renewable resource intensity, reduced pollutant levels, and mitigated contribution to global warming must strive to educate fellow community members. The resultant change in customer preferences (along with the emergence of new applications that the existing technology cannot meet and new regulations that change performance standards) will be a major driver of transition for brands and manufacturers and local stores. When the consumer begins to respond favourably to the “sustainability” marketing/education campaign run by lead consumers/municipality/local stores, the brands and supermarkets will invest in further education of consumer. If there is a cost increment in the product because of the adoption of biopackaging, brands, lead cutomers will have to appraise the consumer of the lower handling and disposal costs of biopackaging, i.e. the lower cost to the environment and other advantages of biopackaging.

4. Waste management infrastructure

Current distribution and storage networks for packaging materials and packaged products in Texel are geared to service synthetic packaging technology. Significant investment may be required to adjust these networks to biopackaging, because of differences in sensitivity to humidity and temperature and their effect on barrier properties and in physical strength. Present waste management infrastructure in Texel is focused on incineration and recycling. The infrastructural actors are HVC and Sortiva. HVC provides all the waste management services for Texel. They collect and transport the waste to the transfer depot ‘The Hamster’, from where it is shipped to Alkmaar for incineration (Green Islands Network, 2015). Sortiva, meanwhile, recycles bulky items, rubble, plastics paper and glass, so that it can be reused for other products. Biopackaging, as reduction at source technique, is much superior to these methods.

The most preferred disposal method for biopackaging is composting. A transition to biopackaging would thus involve an overhaul of the current disposal facilities and perhaps also in collection network in Texel to suit the composting process. This considerable overhauling involved could cause infrastructure to exercise regime inertia. The actors involved may face loss. Biopackaging may minimize the role of existing employees and supply chain and transportation networks.

5. Authorities and regulation:

Authorities such as the municipality in Texel, the Dutch government, the EU are the central control actor in the system, the actor with the greatest agency. Waste management efficiency is a measure of the municipality’s capability to measure more complex services like health and transportation (Hoornweg, Tata, 2012). The advent of biopackaging would be a boon for the municipalities, it could preclude the social discontent that arises among the Texelaars with the boom in tourists and unmanaged waste. The municipality can help the cause of biopackaging by ensuring strict implementation of the regulations concerning biopackaging, discernings investments in composting infrastructure and educating citizens of the merits of biopackaging. The Dutch government or EU could incentivise development of biopackaging among brands and packaging manufacturers through tax breaks, subsidies or minimal production/consumption quotes. The authorities may also act as intermediaries that guide grassroot/community groups from their experiences with similar projects

6. Social groups:

From anecdotes on Texel and through the course engineering for sustainable development, we have learnt that Texelaars are quite conscious about sustainability. There are quite a few grassroot, community based initiatives such as the beach comber movement and the second hand shops in Texel.Such non-governmental and non-corporate actors could vigorously push for the transition to biopackaging. They could contribute to the regime change by influencing customer preferences, expectations through awareness and education drives or as lead consumers. If they are a considerable percentage of the local population, they can become popular movements that can force the authorities and corporates to push for biopackaging.

We see that in the STS of biopackaging, there are some actors that would prefer biopackaging while some do not. A sustainability transition can only be brought about through active governance of change: interaction and negotiation among actors to decide on the trajectory. As the central actor, the authorities should take the position of the prime mover and bring all relevant actors to the table. Negotiation, certain level of horse-trading will be necessary As discursive space at the niche level is much more flexible than in the regimes (Pesch,2015),the biopackaging movement should start out as pilot projects in certain neighbourhoods or streets. Perhaps the grassroot/community initiative groups can help with setting up these niches. These pilot projects are an opportunity to define and modify discursive spaces:visions, expectations, values, opinions, especially among the resistant actors. Learning from the niches can then be used to develop supportive regulations, product specifications and networks.