However, Ghana faced a production decline in the mid-60s, with a lowest level reached in 1983 with a production of 154.000 tons. Despite the fact that production has increased from that point on, it still is less compared to the period in the mid-60s.

This is a result of cultivation, and the low yield per area is also a problem, which attributes to the incidence of pests and diseases. Also a lower producer price and non-adoption of research recommendations is a problem. Farmers won’t receive much for their cocoa the basic operational cost are raised sharply. Due the fact that the global demand of chocolate has risen thirteen percent in five years [nbcnews, 2014]. But Cocobod has not increased the price it pays for cocoa. The farmers still receive 212 cedis (€49) for a 64 kg bag [The Guardian, 2014]. Ghana’s low productivity is a result of deforestation, low income for farmers and workers on small cocoa farms – which is already mentioned - and decreasing of soil nutrients. These are leading factors why Ghana ranked itself lower on the global market [Dorn, 2004].

All these factors summed up, can be explained in one word, ‘inefficiency’. Not too forget, farmers do not have up to date information about the coming weather. The knowledge of the locals is based on the current meteorological agency of Ghana. It is a fact that they sometimes predict false weather forecasts, which is proven throughout the years. The major case was in 2011, when the meteorological agency predicted drought in Northern Ghana, instead floods followed. [Pong, 2014]

COCOA CHAIN

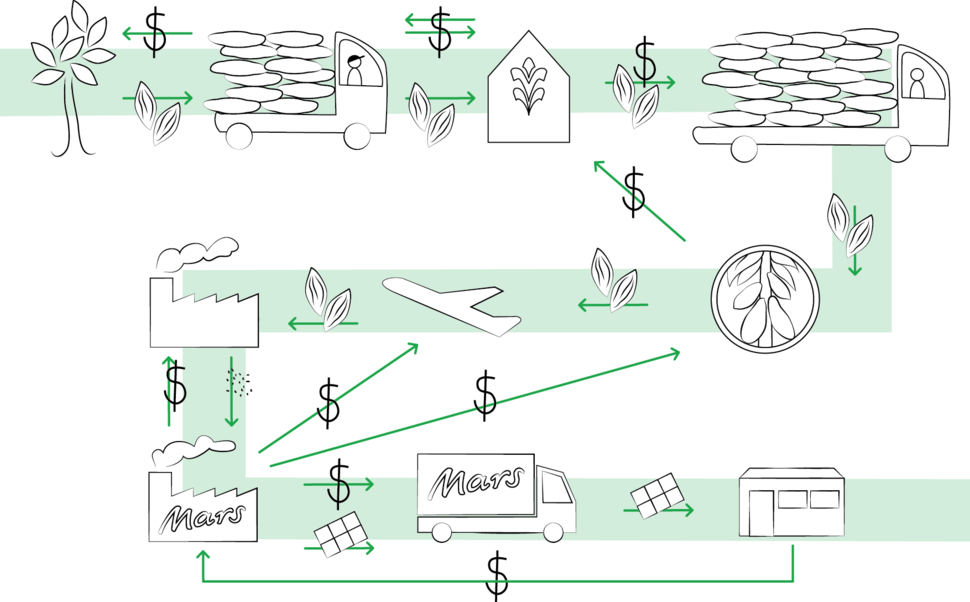

The cocoa chain, which can be seen in "Figure 10. Cocoa chain" on page ?6, starts with the cocoa farmers. They take care of the cocoa trees and during the dry season harvest the cocoa pods. The Ghanaian cocoa trees harvest twice a year, this happens during June/July and the other harvesting period is between September till November. After harvesting the farmers break the pods open and let the beans inside dry in the sun. When dry, the cocoa beans are packed in bags and sold to purchasing clerks of LBCs. This purchasing clerk is most of the time family-related to the owner of the LBC, since this purchasing-clerk has to travel with a lot of money towards the farmers. When the purchasing clerk is not family-related, it often happens that the purchasing clerk disappears with money. But normally, the purchasing clerk provides the farmers with their well-earned money and the LBC of their cocoa. The purchasing clerk stores the bought cocoa in the warehouse of the LBC.

Ghana Cocoa board, Cocobod is a governmental organisation, which claims ‘to encourage and facilitate the production, processing and marketing of good quality cocoa, coffee and sheanut in all forms in the most efficient and cost effective manner, and maintain the best mutual industrial relation with its objectives in Ghana.’ [Cocobod, 2015]. Sometimes it takes weeks before the LBCs get money from Cocobod, because Cocobod needs to check quality standards of the cocoa. Which makes the function of a LBC risky, since they have already paid the cocoa farmers, purchasing clerk and truck driver. QCD comes and checks if the cocoa beans have premium quality in the warehouse of the LBC. If the cocoa beans are premium quality the cocoa beans are sealed and need to wait for transport to the Cocobod warehouse. When the cocoa arrives to the Cocobod warehouse the cocoa is again checked.

Then the cocoa is ready to leave Ghana, which is going to be transported by sea- or air transport towards factories. The factories clean, sort, roast, crack and winnow the beans to make cocoa paste. Then in the same factory or another one, the cocoa paste is pressed to separate the different substances of the cocoa bean. Which can be transformed into cocoa butter and cocoa powder. The different substances are mixed together in different proportions, to create the flavour of the chocolate of a specific type of product of that brand, in this case Mars. Different ingredients are added, like nuts, caramel and sugar, to make the chocolate bar as everyone expects it to be. The bar is shipped to the store to be sold to the customers. At the end the price the customer pays is sometimes 100 times more then the cocoa farmer gets for it.