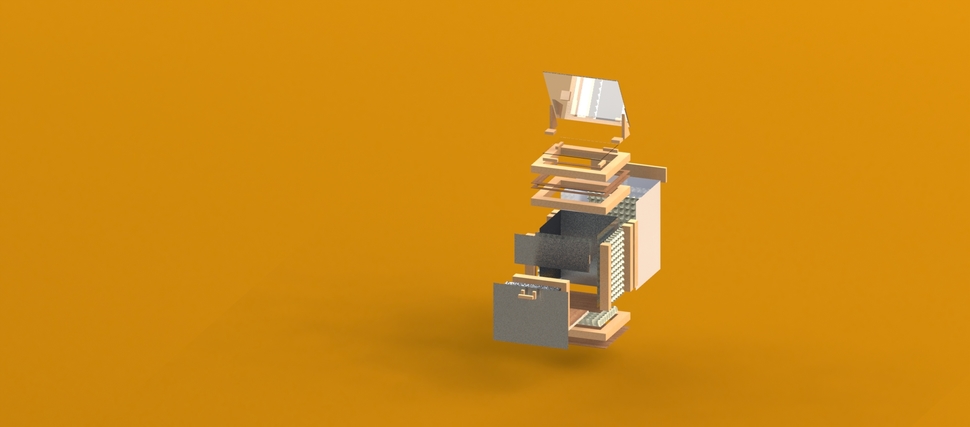

The design

Because the Wood Gas Stoves were still being shipped to Morocco while building the first prototype, and because we hadn’t found suitable fuel for them yet, the solar box is accommodated with a gas hob as heat source. Gas is also a well-researched and reliable heat source, which made it possible to focus on the solar box completely. The construction of the main frame was thought out beforehand, whereas the construction of other parts arose while building.

The box

The insulation of the box was the main focus of this design. The dimensions of the first prototype are based on the size of most often used pans in Morocco. As pressure pans are often used, the design ended up being quite high.

The main structure of the Fortune Cooker resembles a cuboid. Six vertical beams are supported by one of the horizontal rectangles. Two in front and four in the back, of which the rearmost are turned 90°. The beams in turn support the remaining two rectangles. The rearmost beams in the back are added to ensure that a galvanised steel sheet and gliders of the drawer could be attached to the inside of the box.

The upper horizontal rectangle holds the glass in place on the frame. The glass plate is smaller than the top surface of the frame, both because it enables us to create height with splints – and thus make sure that the upper rectangle does not rest on the glass – and because it makes it possible to screw the upper rectangle to the rest of the frame.

This design contains two glass plates placed at a 2,5 cm distance from each other, because the box loses most of its warmth through the glass. The air between the two plates cannot circulate and therefore, it ensures a higher insulation value a single glass plate. The upper glass plate rests on four wooden chunks of the same size, which are glued to the lower glass plate.

The inside of the frame is covered with a sheet of galvanized steel, which has two advantages; the galvanisation reflects sun rays within the box, and because it is just one sheet, folded to the right size for the inside of the box, the occurrence of possible cracks is minimized.

The insulation of the solar box is done with used egg cartons, both because it is a good use of material that otherwise would have been wasted, and because it insulates quite well when multiple are put on each other. In this design, three layers of egg carton are placed and fitted in each side of the frame, except for the front and top. Afterwards, the outer frame is covered by another sheet of galvanised steel.

The drawer

The idea of the drawer was introduced by Jan Kluiver, with the assumption that a drawer will offer the best user experience, as it is easier to reach the pan from above. The construction of a drawer by ourselves is not easy and therefore we designed it as easy as possible. The most important aspects are the insulation of the drawer’s front and the fit between the drawer and frame. The height of the drawer was again based on the size of pans in Morocco. The drawer is as small as possible, to make the hole that appears while opening the drawer as small as possible. In this way the loss of warmth is minimized when the drawer is opened. The insulation of this panel is as important as the insulation in the rest of the frame. The egg cartons were therefore fit in the front part of the drawer frame, strengthened with two small pieces of wood in the corners of the frame, and covered by fitted press plates.

The mirror

The mirror reflects makes sure that even more sun rays are collected in the box. The position of the sun determines the angle between the mirror and the top of the box. We had initially planned to attach the mirror to the box by hinges, but it turned out that the way in which the solar box is constructed prohibited an easy way to do this. Therefore we decided to position the mirror by letting it rest on variable pairs of triangles, each pair with one unique angle.

Details

Wheels is supported by four wheels, so the Fortune Cooker can easily be moved around the house and positioned towards the sun. The handle on the drawer is essential to open it properly. The gas hob is placed in such a way, that it is easy for the user to operate the know. Therefore, the hole that should accommodate the hose for gas supply is in the front part of the drawer.

Building experiences

After collecting all of the needed materials in Saïdia and Oujda we were ready to build the first prototype. Since the Fortune Cooker had never been built completely, things needed to be thought through quite thoroughly. Nevertheless, our ability to solve problems was being tested during the building process, as Moroccan resources are very different from the ones in known Dutch workshops. Our biggest encounters are described below, a full description of the building process can be found in Appendix 5.

First of all we discovered that Moroccan dimensions are not that strict. The width of the beams could change along its length and angular profiles are not perpendicular. It was therefore very difficult to fit the frame solidly together without cracks. Secondly we were unable to cut glass by ourselves, which we solved by going to the glasscutter by taxi. Another example of one the hurdles we had to take, is that galvanised steel sheets are thicker and thus much tougher than aluminium sheets. The aluminium sheets arrived from The Netherlands while we were finishing up the drawer. Aluminium is softer than galvanised steel and is easier be cut or stapled.