First prototype

Choice of materials

For the first prototype we decided to make a combustion chamber out of metal instead

of clay. This was done because of the fact that the construction is much faster, the construction

costs are less and old barrels can be used, which makes it sustainable.

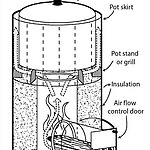

Rocket Stove based design

The design for the first prototype was based on the rocket stove design (see the picture

above). The cookstove consists out of a combustion chamber, a wood inlet and a large

barrel that is used as the outer case of the cookstove. No chimney was added to the

design because when the chimney is placed lower than the pot, it would only cause

heat losses. In order to make a sufficient airflow the prototype is designed in such a way that the area through which the air flows is the same everywhere the air should

flow. All the main parts can be made out of old paint barrels. However, it is important

that the barrel used for the construction of the combustion chamber is clean. Otherwise,

the remains of the paint will burn when the fire is burning inside the combustion

chamber and thus it will release toxic smoke. This prototype was designed for a pot

with a radius of 30 cm.

The combustion chamber

For the combustion chamber a diameter of 20 cm and a height of 60 cm was chosen.

From ‘Design principles for wood burning cook stoves’ (Bryden, M., e.a.) it was concluded

that a combustion chamber with a diameter of 20 cm would be sufficient for kenkey

makers. In the same document it states that the height of the combustion chamber

should be three times the diameter. The diameter of the wood inlet should be the same

as the combustion chamber, thus 20 cm. The length was chosen to be 27 cm. This way

it is possible to make two combustion chambers and two wood inlets out of one clean

barrel.

The outer barrel

The pot will be placed partly in the outer barrel. Where the pot is placed the diameter

of the outer barrel has to be 63 cm, in order to keep the area through which the air

flows the same size everywhere. To increase the diameter, eighteen cuts are made in

the barrel and the eighteen flaps are bend outwards. The grid is placed where the flaps

begin and the grid should be placed 4 cm above the combustion chamber. The total

height of the barrel is 87 cm, so the flaps will have a height of 24 cm.

The space between the combustion chamber and the outer barrel is filled with insulating

material. For the prototype a mix of ash and rice husk was used.

Grids

The grid is made out of iron rod; a ring with a diameter of 58 cm and four pieces of iron

rod with a length of 49 cm. A second ring of iron rod is placed at the top of the flaps in

order to strengthen the cookstove and to make sure the barrel will have the right diameter.

This ring has a diameter of 63 cm. Two handles can be made from the remaining

parts of the iron rod.

Second prototype

The second prototype is comparable with the first prototype, only a few adjustments

to the design are made. These adjustments will all be explained below.

The combustion chamber

The combustion chamber and the wood inlet are both made shorter and wider. The

new length was 40 cm and the increased diameter was 25 cm. The length was chosen

to be 40 cm, because this height is more suitable for cooking. The first prototype was

too high to cook kenkey on. The diameter is increased, because it turned out that the

wood inlet was too narrow.

The outer barrel

The outer barrel is also shortened. The top 9 cm are cut off and the slits between the

flaps have a depth of 34 cm. A third ring was added on top of the cookstove. So now

there are three rings, two with a circumference of 2 m on both the top of the barrel

and 20 cm under the upper ring and one with a circumference of 1,78 m at a height of

44 cm above the ground. The last ring will make the grid. In the second design the grid

is removable. A cover for the insulation materials is made out of the top of the barrel.

Stability

Lastly four iron bars are added as a stand. These bars have a height of 5 cm and a length

of 10 cm. These dimensions can differ a little if another bar is available. The stand will

make the cookstove more stable and will allow air to flow underneath the fire.

The building manual can be found in Appendix A.